Assessing Network Requirements to Determine Fiber Optic Needs

- Sep 11th 2025

Choosing the right fiber optic cables can be a complex process. While some customers know exactly what they need, many don't. If you're unsure about the specifics for your network, our fiber solutions team here at Cables Plus is here to help. We'll ask you a series of questions about your bandwidth needs, network environment, and other critical details to ensure you get the right solution the first time. Here’s a breakdown of how we assess network requirements to find the perfect fiber cabling fit for you.

Questions to Ask to Find the Right Fiber Optic Cables

- Where is the cable going? Indoors or outdoors?

- Do you need singlemode or multimode fiber?

- How many fibers do you need in your cable?

- What length does the cable need to be?

- What connectors do you need?

- How long do the breakout legs need to be?

- Do you need a pulling eye?

What Type of Fiber Do You Need?

The first question our team will ask is whether you need singlemode or multimode fiber. Your project specification should indicate which glass type is required, and the choice depends primarily on distance, bandwidth, and cost.

Singlemode and multimode fiber both supports speeds of 1 to 800 Gig. Singlemode fiber, referred to as OS1/OS2, supports much longer distances—up to 40 km or more, depending on the speed. Multimode fiber comes in OM1 (legacy), OM3, OM4, and OM5 (OM2 is obsolete) and supports much shorter distances. The table below highlights the maximum distances supported by each fiber type based on current industry standards for Ethernet applications.

|

Type |

1 Gig |

10 Gig |

25 Gig |

40 Gig |

50 Gig |

100 Gig |

200 Gig |

400 Gig |

800 Gig |

|

Multimode Fiber |

|||||||||

|

OM1 |

275 m |

33 m |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

OM3 |

1,000 m |

300 m |

70 m |

100 m |

70 m |

100 m |

70 m |

70 m |

60 m |

|

OM4 |

1,100 m |

400 m |

100 m |

150 m |

100 m |

150 m |

100 m |

100 m |

100 m |

|

OM5 |

1,100 m |

400 m |

100 m |

150 m |

100 m |

150 m |

100 m |

150 m |

100 m |

|

Singlemode Fiber |

|||||||||

|

OS1/OS2 |

5 km |

40km |

40km |

40km |

40km |

80km |

40km |

40km |

2km |

In addition to distance and bandwidth requirements, total system cost is a key factor when choosing a fiber type. While singlemode cable is required for longer distances, high-power singlemode transceivers needed for those long distances are significantly more expensive than multimode transceivers, increasing overall system cost. This is especially true for links longer than 2 km, which use wavelength division multiplexing (WDM) technology that sends signals over multiple wavelengths.

For shorter distances of 500 m or less, cost becomes a more critical deciding factor. For short-reach singlemode applications that support up to 500 m and don’t rely on WDM technology, total system costs are much closer to multimode and may even cost less in some scenarios. Our solutions team can help you determine which fiber type you need for your application and budget.

What is Your Strand Count?

Our team also needs to know how many strands of fiber you need. Lower-count fiber cables come with 2, 4, 6, or 12 fibers, and higher-count cables come with 24 or more fibers, usually in multiples of 12 (e.g., 24, 36, 48, 72, 144, 288). Custom fiber strand counts are also available, but typically require a large minimum quantity and longer lead times.

The number of fiber strands is determined by the installation requirements, such as the number of switches or devices being connected and the type of application. A single duplex application requires two strands of fiber—one for transmitting and one for receiving. If you need to support multiple duplex applications, it is more cost-effective to purchase a higher-strand-count cable rather than multiple two-strand cables. Cables with higher strand counts also take up much less space in racks and pathways than using multiple lower-count cables.

Adding more fiber strands than needed on day one is typically recommended to support future growth, especially for backbone infrastructure in LANs. For example, while a LAN might need only six strands of singlemode fiber to each telecommunications room to support three duplex connections today, extra strands can be used for future upgrades and increased bandwidth demands without having to purchase and install additional cables.

Higher bandwidth speeds may require more strands if the application uses parallel optics technology, where multiple strands transmit and receive at speeds of 10, 25, 50, or 100 Gigabits per second (Gb/s). For example, current 800 Gig multimode and singlemode Ethernet applications use 16 fibers, with 8 transmitting and 8 receiving at 100 Gb/s.

Environment and Installation Matter

The environment where the fiber cable will be installed and how it will be installed are also important details our solutions team needs. The first question is whether the cabling will be installed outside or inside. Outside plant cables are constructed to withstand the elements, while indoor cables are designed to specific fire ratings as per building codes.

The environment where the fiber cable will be installed and how it will be installed are also important details our solutions team needs. The first question is whether the cabling will be installed outside or inside. Outside plant cables are constructed to withstand the elements, while indoor cables are designed to specific fire ratings as per building codes.

Outdoor fiber optic cable is typically a loose tube construction, which features bare 250-micron (or 200-micron) fibers housed inside a plastic tube with water-blocking technology. Indoor fiber optic cable is typically tight-buffered construction, which feature 250-micron fibers with a 900-micron protective layer surrounded by aramid yarn. There are also indoor/outdoor tight-buffered cables that can traverse between buildings and feature some form of water blocking to prevent ingress.

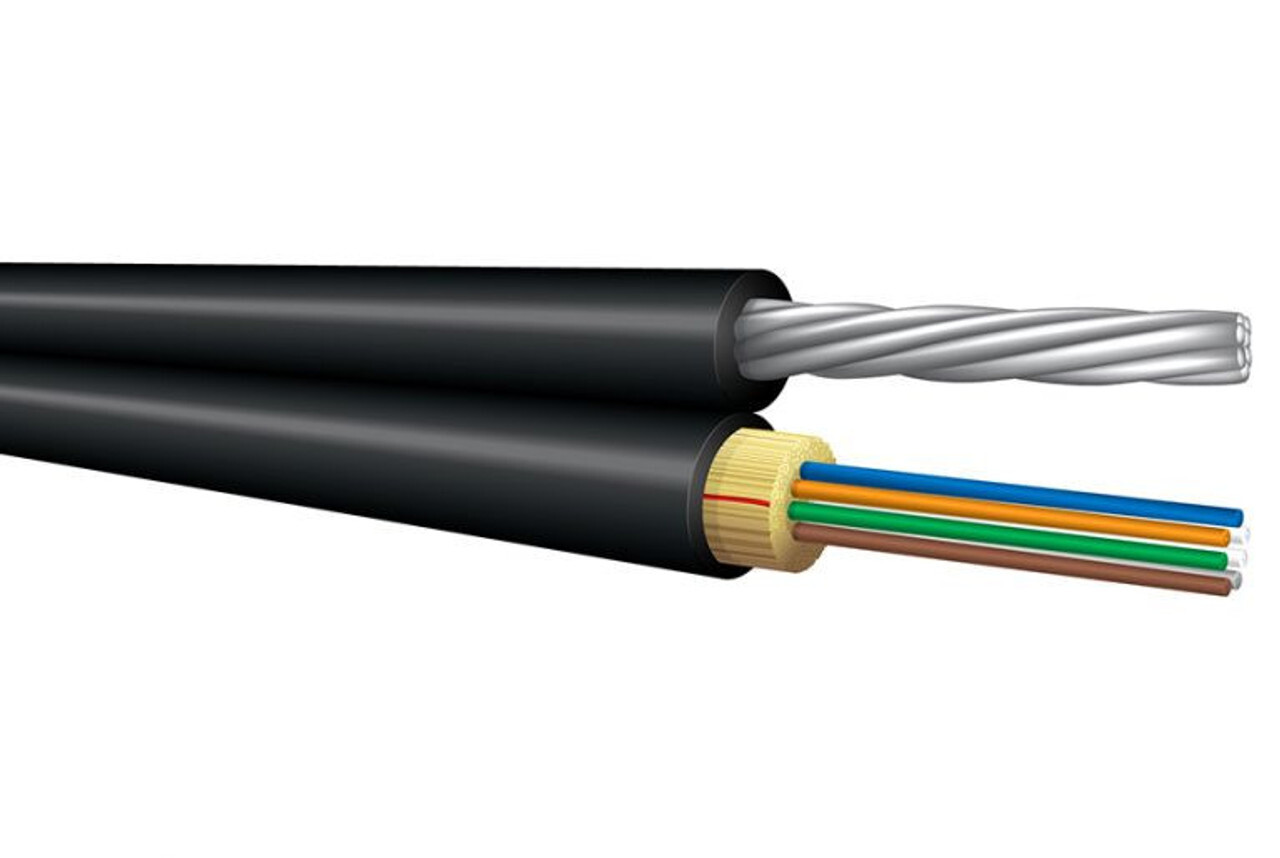

It's also important to know how the cables will be installed. Outdoor cables can be installed as direct buried, buried in conduit, or aerial. If the cable will be deployed as aerial, it’s important to know if the cable will be lashed to existing cabling infrastructure using a separate messenger wire or self-supporting using a figure-eight construction. Ideal for new deployments, figure-eight cables feature integrated support strands that eliminate the need for lashing, allowing for an easy, one-step installation that reduces labor by approximately 50%. The presence of existing infrastructure, span distance, and fiber strand count can impact which type of aerial cable you need.

For indoor cables, it’s important to know if the cable will be installed in air-handling spaces (like in a wall or above a drop ceiling) or in pathways or shafts that extend vertically through a building. Building codes require cables installed in air-handling spaces to have a plenum (OFNP) jacket rating, while those traversing from one floor to another can have a riser (OFNR) rating. These ratings determine the ability of a cable to resist the spread of fiber and limit smoke emissions. It’s also important to know if cables will be installed in innerduct, which is also available in plenum and riser ratings. Additional information is needed to determine the right innerduct type, size, and rigidity, such as diameter of the cables, the required Dimension Ratio for the environment, and any color-coding.

For both outdoor and indoor cables, location and application may also dictate compliance with a specific industry standard or code. For example, military applications may require the cable to be rated as MIL-SPEC, as defined by the Department of Defense, while cables used in mining applications may require MSHA compliance, as set by the Mine Safety and Health Administration.

Pre-terminated Assemblies

If your project requires pre-terminated fiber assemblies, such as those used in switch-to-switch and switch-to-server links in the data center, our team will need additional key information since these assemblies are made to order.

- Length: Knowing the exact distance between the equipment you’re connecting is essential to avoid ordering assemblies that are too short and won’t allow you to connect. While you want some slack, ordering assemblies that are too long can make them difficult to manage and more susceptible to damage.

- Connectors: You will need to know the number and type of fiber connectors for both ends of the pre-terminated assembly based on the equipment you’re connecting. For duplex applications, this will likely be LC connectors, but could be SC, ST, or very small form factor CS, SN, or MDC connectors. For trunk cables and parallel optics applications, this will likely be multi-fiber connectors, such as MPO/MTP or MMC connectors. For multi-fiber connectors, you will need to know the polarity and if the connectors are pinned or unpinned.

- Breakout configuration: For breakout cables with different connectors on each end (e.g., MPO/MTP to LCs), you will need to know the fanout length for the breakout portion of the assembly based on the equipment you’re connecting. You also need to know whether you need staggered connectors on one or both ends to easily connect different ports and maintain a neat, organized installation.

Pulling eye: Our team will also ask if you need pulling eyes on one or both ends of your assemblies. For pre-terminated assemblies installed over longer distances through pathways, pulling eyes protect cables and connectors by properly distributing tension and minimizing cable twisting during installation.

Pulling eye: Our team will also ask if you need pulling eyes on one or both ends of your assemblies. For pre-terminated assemblies installed over longer distances through pathways, pulling eyes protect cables and connectors by properly distributing tension and minimizing cable twisting during installation.

We’re Here to Help

While being prepared and knowing all your network requirements can certainly help minimize guesswork and streamline the process of choosing the right fiber cable, we understand that you may not have all the specifications at your fingertips. We also understand that there is no “one-size-fits-all” solution, and every application and installation is unique.

The good news is that Cables Plus has a dedicated, highly trained, and experienced solutions team to help decipher your specifications and ask the right questions to determine the best fiber cables for your specific environment and application. Our team can also work with you to provide custom-built, end-to-end solutions using only top-quality cabling and connectivity, ensuring you are equipped with high-performance fiber cables for your unique application. Contact us today for all your fiber cable needs.

Explore Our Complete Range of Fiber Solutions Contact an Expert