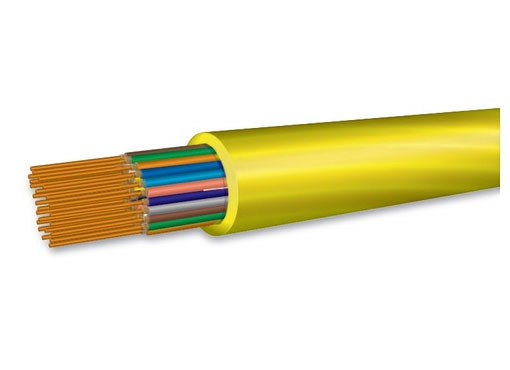

Breakout 12 Fiber Singlemode Bend Tolerant Ultra-Fox™ Indoor/Outdoor Plenum Yellow Jacket

| Tensile Load | Minimum Bend Radius | ||||||||

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | BX002K***9*P | 6.3 (0.25) |

46.0 (31.0) |

1,600 (360) |

400 (90) |

9.5 (3.7) |

9.5 (3.7) |

||

| 4 | BX004K***9*P | 6.3 (0.25) |

46.0 (31.0) |

1,600 (360) |

400 (90) |

9.5 (3.7) |

9.5 (3.7) |

||

| 6 | BX006K***9*P | 7.4 (0.29) |

61.0 (41.0) |

2,400 (540) |

600 (130) |

11.2 (4.4) |

11.2 (4.4) |

||

| 8 | BX008K***9*P | 8.7 (0.34) |

88.0 (59.0) |

3,200 (720) |

800 (180) |

13.1 (5.2) |

13.1 (5.2) |

||

| 12 | BX012KSLA9YP | 10.0 (0.39) |

105.0 (71.0) |

4,800 (1,080) |

1,200 (270) |

15.0 (5.9) |

15.0 (5.9) |

||

| 18 | BX018K***9*P | 12.2 (0.48) |

162.0 (109.0) |

6,000 (1,350) |

1,500 (340) |

18.3 (7.2) |

18.3 (7.2) |

||

| 24 | BX024K***9*P | 14.2 (0.56) |

221.0 (148.0) |

7,200 (1,620) |

1,800 (400) |

21.3 (8.4) |

21.3 (8.4) |

||

| 36 | BX036K***9*P | 15.7 (0.62) |

274.0 (184.0) |

9,600 (2,160) |

2,400 (540) |

23.6 (9.3) |

23.6 (9.3) |

||

| 48 | BX048K***9*P | 18.4 (0.72) |

376.0 (253.0) |

12,000 (2,700) |

3,000 (670) |

27.6 (10.9) |

27.6 (10.9) |

||

Glass Type

- SLA Bend Insensitive Low Water Peak Single Mode ITU-T G.657.A1 and ITU-T G.652.D

- Core/Cladding Diameter (μm) 9/125

- Wavelength (nm) 1310/1550

- Gigabit Ethernet Distance (m) 5km

- 10-Gigabit Ethernet Distance (m) 10km

- Maximum Cabled Attenuation (dB/km) 0.5/0.5

Applications

- Ideal for installations requiring an extremely rugged and reliable cable design where maximum mechanical and environmental protection are required

- Installed in ducts, plenums, and air handling spaces

- Easiest cable to install where direct termination of the subcable to a connector and a direct run to panels and equipment are desired

COST SAVINGS

- Direct termination to subcable may eliminate the need for patch panels and patch cords and reduce connector loss

- 900 µm buffer eliminates the need for costly and time-consuming installation of fanout kits or pigtail splices because connectors terminate directly to the fiber

- High crush resistance may eliminate the need for innerduct

Features

- High performance components and construction

- UL Listed in accordance with NEC sections 770.179(a) for use in ducts, plenums and air-handling spaces

- Most rugged and easy to install cable design for enterprise cabling applications

- Standard 2.0mm subcables can be directly terminated with standard connectors. 2.5mm and 2.9mm subcable sizes are also available

- Subcabled fiber is environmentally and mechanically protected

- Ideal for use in point-to-point runs in adverse environments

- Direct termination to subcable provides additional strain relief for better connector retention during moves, adds, and changes

- Design is ideal for direct pulling with mesh grips

- Cable materials are Indoor/Outdoor - UV, water and fungus resistant

- Wide operating temperature range of -40°C to +85°C

- High performance 900 µm tight-buffered coating on each optical fiber for environmental and mechanical protection

- Jacket highly chemical resistant for installation in harsh industrial environments

- Interlocking armor can be applied to cables as an alternative to conduit installation

- 2 to 48 fibers

Standards

Optical Cable Corporation Indoor/Outdoor tight-buffered fiber optic cables meet the functional requirement of the following standards:

- UL 1651

- ANSI/NFPA 262

- GR-409-CORE

- ICEA-S-104-696

- ICEA-S-83-596

- TIA-568

- TIA-598