How to Find and Repair Breaks in a Fiber Optic Cable

- Oct 29th 2024

Fiber optic cable is the primary media for outside plants, campuses, and LAN backbone infrastructure because it can transmit more data farther. It also comprises the majority of data center switch-to-switch and switch-to-server links that transmit high volumes of data at faster speeds. It’s even increasingly making its way into horizontal infrastructure for connecting devices at extended distances and delivering bandwidth for demanding applications like high-throughput Wi-Fi and augmented and virtual reality.

As the mainstay of the connected world, fiber optic cable must be kept in optimal condition to keep critical networks up and running. While fiber optic cables are generally quite durable when correctly handled, defects and damage can happen. Cracks and breaks are of particular concern since they can cause data transmission to cease altogether. When these failures occur, they can cause costly network downtime. The solution is to locate and repair these breaks as quickly and efficiently as possible.

Causes of Fiber Optic Breaks and How to Avoid Them

Cracks and breaks in a live fiber optic cable can happen for various reasons. Sometimes cables are accidentally severed from a backhoe or other construction actions or completely chewed through by rodents. Damage can also be caused by defects during manufacturing, but a primary cause is mishandling of the fiber.

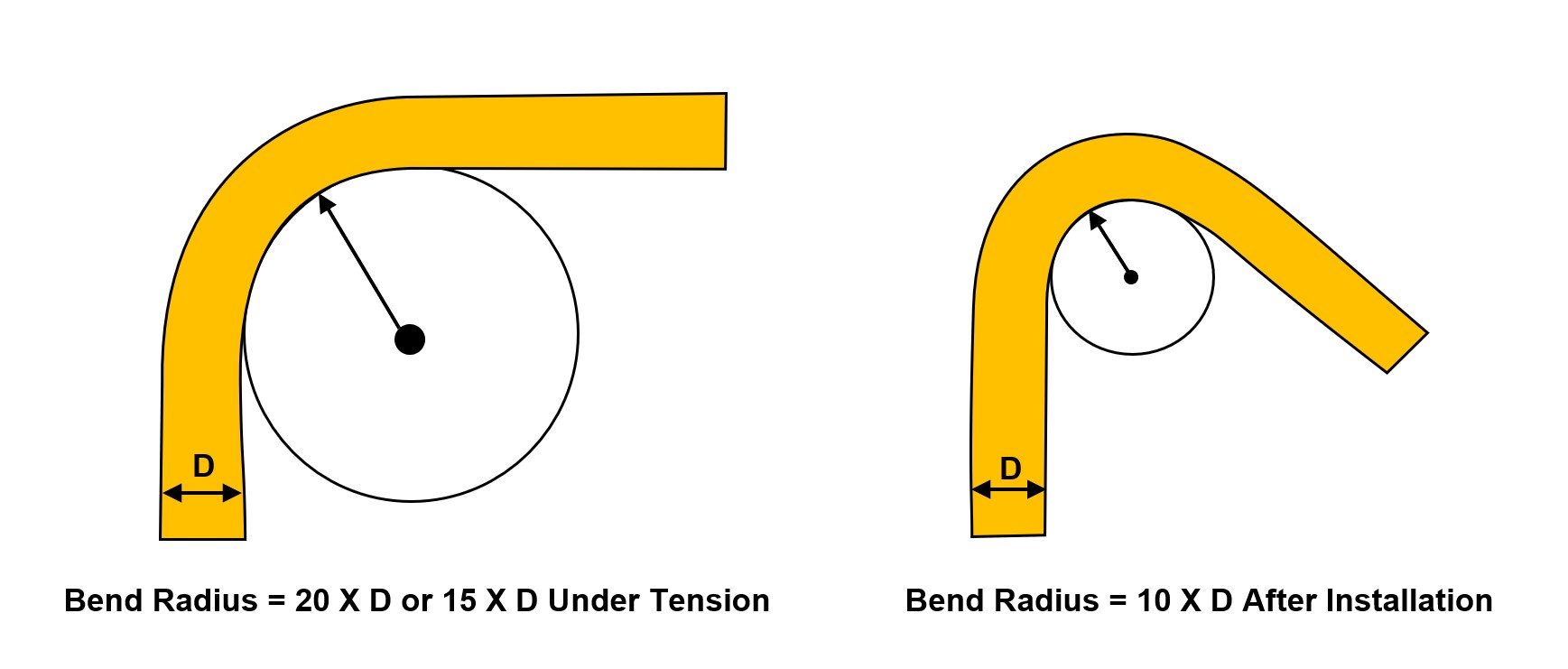

Fiber optic cable typically has a minimum bend radius of 20X the diameter of the cable during installation (i.e., under tension) and a minimum bend radius of 10X the diameter after installation. Some bend-insensitive fiber cables can handle a minimum bend radius of 15X the diameter under tension. When fiber bends exceed the minimum bend radius, it can cause light signals to leak out of the fiber, significantly increasing insertion loss (i.e., attenuation) and degrading transmission performance. It can even cause the glass of the fiber to break. This typically happens during installation when routing cables through cabinets or coiling them too tightly into a service loop. It’s imperative to check the mechanical specifications of the fiber to be aware of the minimum bend radius and avoid making sharp bends that can exceed the specification.

Microbends can also cause cracks and breaks in fiber. These small and often unseen bends typically occur when external stresses compress the fiber. This can occur during cable manufacturing, when the fiber is compressed by a vehicle or other heavy object on the job site, or when it accidentally gets pinched during installation. It can even happen in outside plant environments when freezing temperatures cause the ground to shift. Sometimes microbends go unnoticed and don’t immediately impact fiber performance, but over time, they eventually cause the fiber to break. Avoiding microbends involves paying close attention to how the fiber is handled, protecting fiber with conduit or armored cable, and purchasing cable from a reputable source.

Other causes of breaks in a fiber optic cable include overtwisting the cable during installation and exceeding the cable’s maximum pull tension rating. Excessive tension doesn’t always result in an obvious break but can create small fractures in the glass of the fiber that significantly degrade or prevent signal transmission. It’s essential to know the specified maximum pull tension of the fiber, which can vary based on fiber type. Maintaining a smooth, uniform pull during installation can prevent too much pulling force.

Finding a Break in a Fiber Optic Cable

If a fiber link isn’t functioning, the first step is to check for continuity. One of the easiest ways to check for continuity is to use a visual fault locator (VFL). VFLs work by emitting a visible bright red laser beam of light down the fiber link. No light visible at the end of the link typically indicates a break.

The location of the break can be found by looking for where the light from the VFL is leaking out of the cable. However, this isn’t always feasible in a very long link or where the cable isn’t visible, such as in an armored cable or where the cable is behind walls, in conduit, or underground.

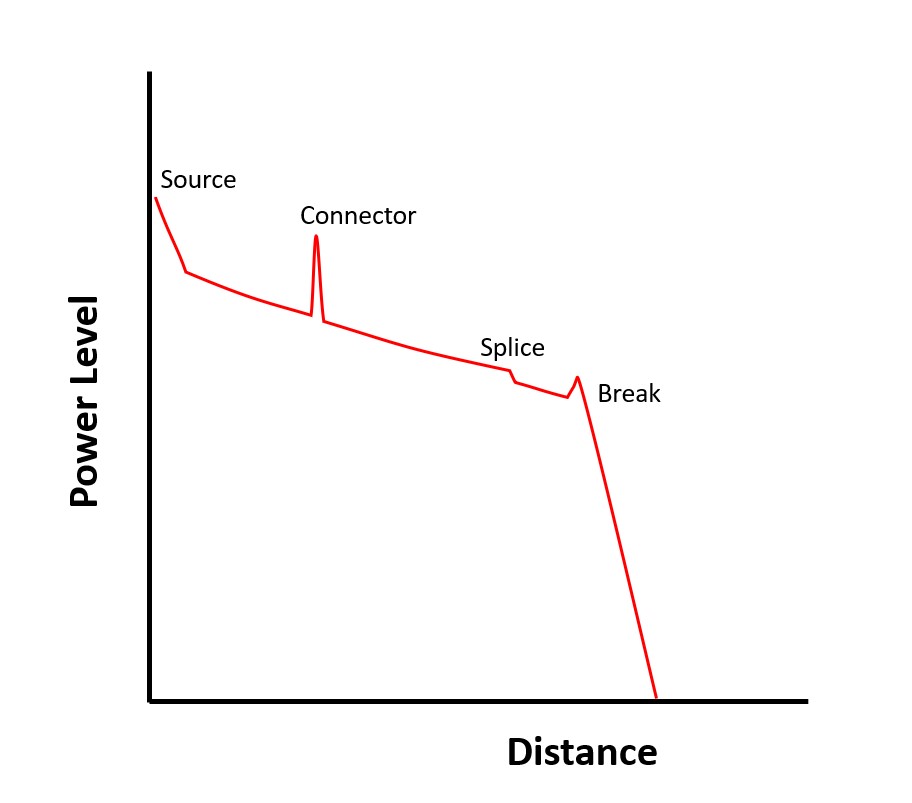

If you can’t locate a break in the fiber using a VFL, the next step is to use an optical time-domain reflectometer (OTDR). OTDRs inject a light signal into the fiber and measure the amount of signal reflected back to the source. These reflections are plotted in an OTDR trace that shows each event and its loss along the length of the link. A break in the fiber cable is typically displayed by a sudden drop in the trace, indicating complete signal loss. This differs significantly from other events on the trace, such as connectors and splices. The benefit of using an OTDR is that the trace also indicates the distance to the break from the source, making it easy to pinpoint the precise location.

Can You Repair a Broken Fiber Cable?

Thankfully, it is possible to repair breaks in a fiber optic cable. One option is to cut out the portion of damaged fiber, strip the fiber, cleave the ends using an optical fiber cleaver, and terminate to a connector. You can then use a fiber optic coupler to join the terminated fibers. A potential issue with this method is that it introduces the loss of the connector into the link. While this may be feasible in a fiber link that offers plenty of insertion loss headroom, the loss is often too high and can cause the link to exceed the maximum insertion loss allowed for the application.

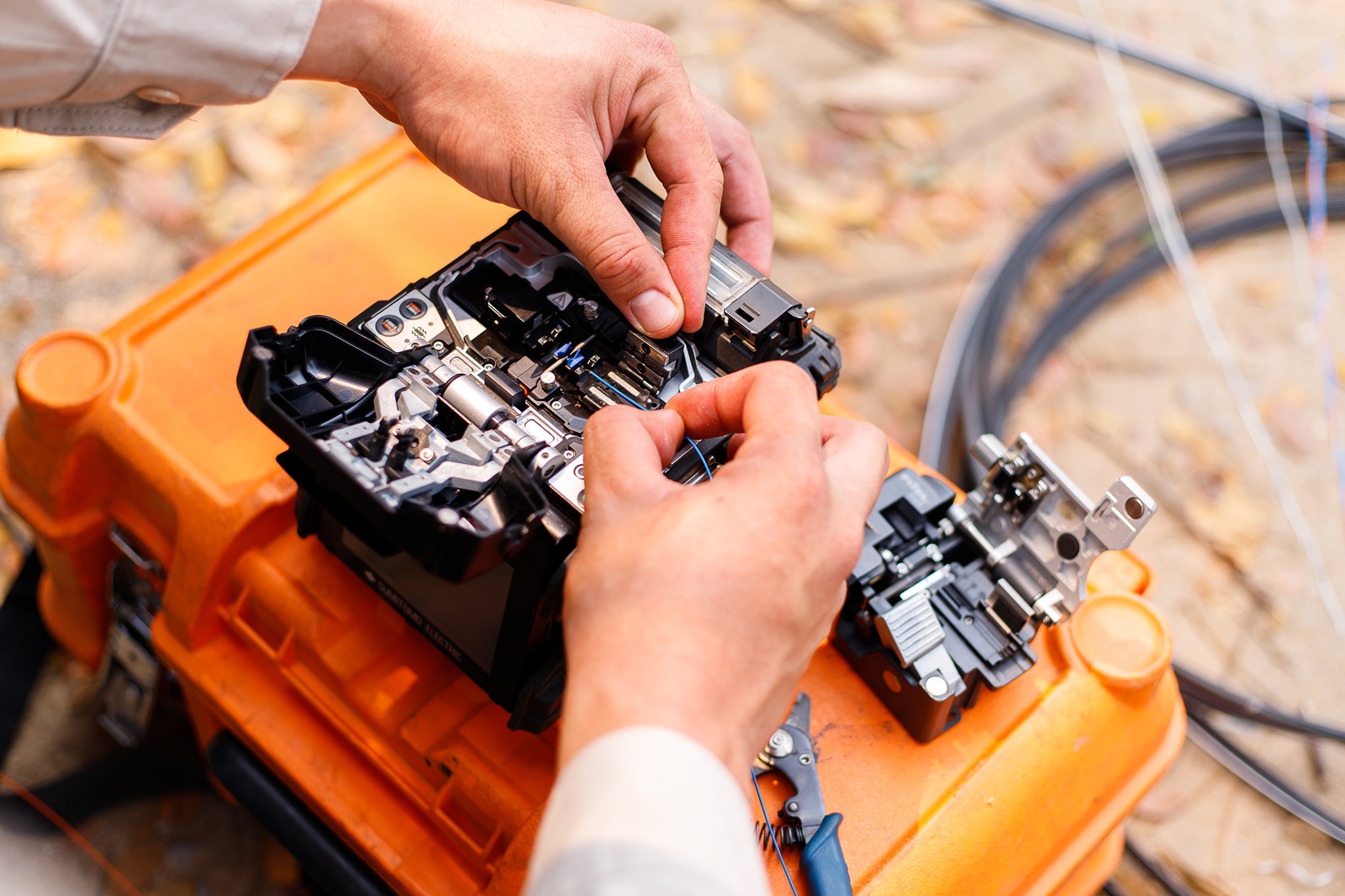

The other option is to splice the fiber using a fusion splicer. Fusion splicing is the lowest loss option for joining two fibers and is typically considered the strongest and most reliable connection. This makes it the preferred method for repairing fiber breaks.

Fusion splicing works by welding cleaved fibers together using an electric arc. Fusion splicers are available for single fibers or as a mass fusion splicer for ribbon cable that contains multiple fibers. After splicing, it’s important to place the splice into fusion splice protection sleeve. These sleeves are easy to apply and are designed to carry tensile, bending, and torsional loads across the splice joint. Most sleeves are heat-shrink sleeves that require gentle heating to complete the process. Sleeves also often include a metal rod to act as a strengthening member. Splices in harsh and outdoor environments should be placed in a fully gasketed splice enclosure to prevent water ingress and designed for above and below grade applications.

How Do You Know if a Fiber Cable Repair Was Successful?

After repairing broken fiber, testing the fiber can verify if your repair was successful and ensure that the link can again support the application. Testing can be done with an optical power meter and light source to ensure that the total insertion loss of the link will support the application. However, to truly know how well your repair worked, only an OTDR will show you the loss of the specific connector or splice at the repair location. If you used an OTDR to locate the break in the first place, using one again also means you have a benchmark to compare the link before and after repair.

The good news is that CablesPlus offers everything you need to deal with breaks in fiber optic cable. Efficiently locate fiber breaks with our full range of VFLs and OTDRs, repair the fiber with couplers and fusion splicing solutions, and ensure your network is up and running correctly with our fiber optic test equipment. Contact us today for all your fiber needs.

Explore Our Complete Range of Fiber Optic Testing Equipment Contact an Expert