Finding the Right Size Innerduct Conduit for Fiber Optic Cable

- Sep 30th 2024

Premise innerduct is a flexible, non-metallic, corrugated raceway that has long been an essential conduit system for protecting fiber optic cables installed throughout telecommunications spaces and pathways. It can help isolate fiber to prevent damage from other cables or trades working in those spaces.

Premise innerduct is available in a variety of sizes. Selecting a size that ensures sufficient space between the cables and the innerduct wall to accommodate pulls and bends without exceeding the fiber bend radius is crucial. The size of the innerduct you choose should also provide space for future growth.

Let's take a closer look at how to right-size your fiber innerduct conduit.

How to Size Conduit for Fiber Optic Cable

To ensure room for future growth, industry standards recommend planning telecommunications pathways for an initial fill ratio of just 25% and a maximum fill ratio of 40%. While 40% is a good rule of thumb for pathways to meet present and future cable installation requirements, most telecom professionals aim for a maximum fill ratio of 70 to 80% for fiber innerduct.

The fill ratio is calculated by dividing the outer diameter of the cable by the inner diameter of the innerduct. If multiple cables are being pulled into one innerduct, the sum of the outer diameters of each cable is divided by the innerduct interior diameter. Knowing the outer diameter of the cables you're installing is essential to choosing the right innerduct size.

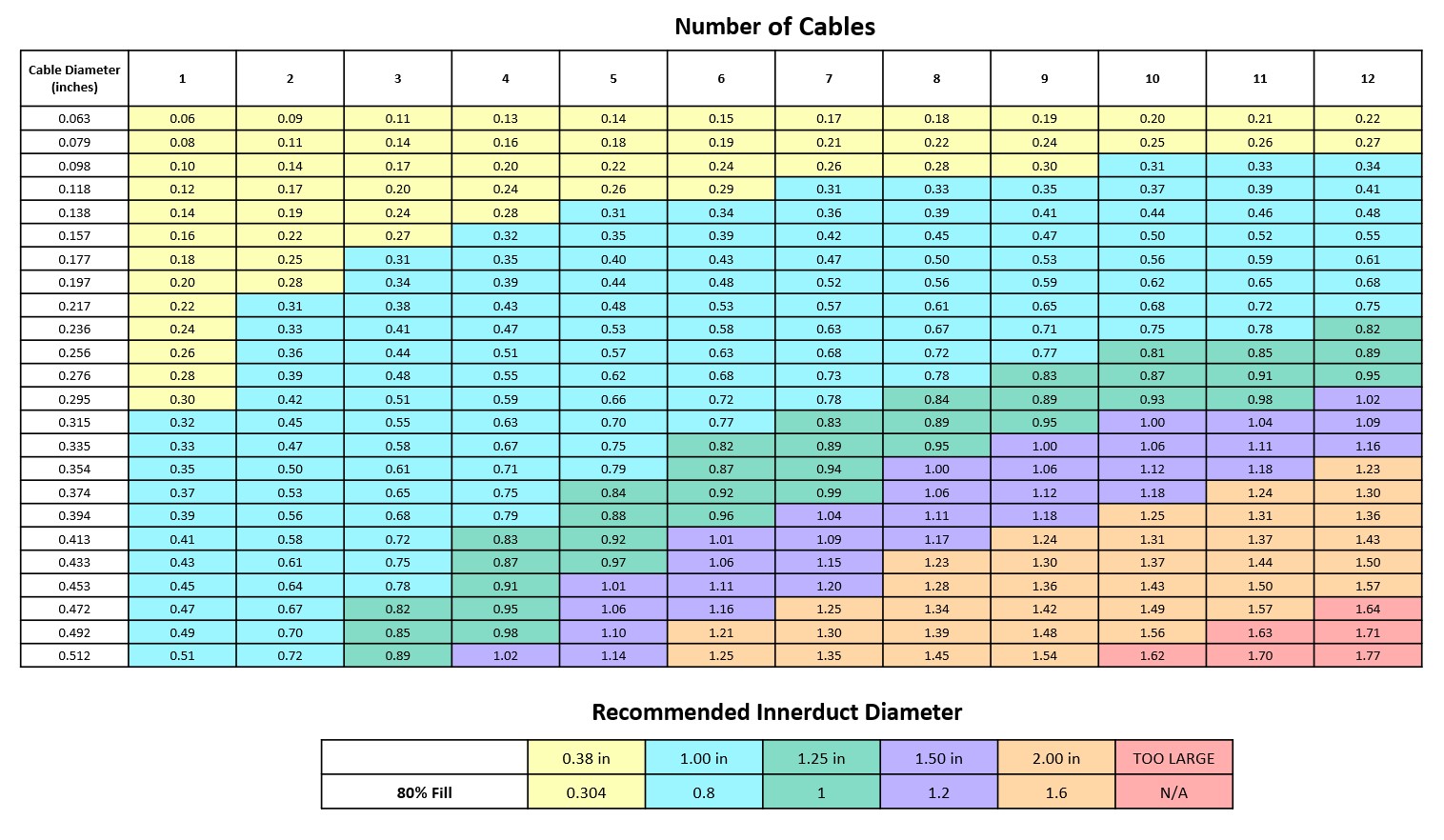

Fiber Optic Conduit Fill Chart

CablesPlus offers six sizes of fiber innerduct – ¾ inch, 1 inch, 1 ¼ inch, 1 ½ inch, and 2 inch innerduct. CablesPlus developed the following fill ratio chart based on the outer diameter and number of cables being installed and a maximum fill ratio of 80% to simplify the process of selecting the right size.

How to Use Fiber Innerduct

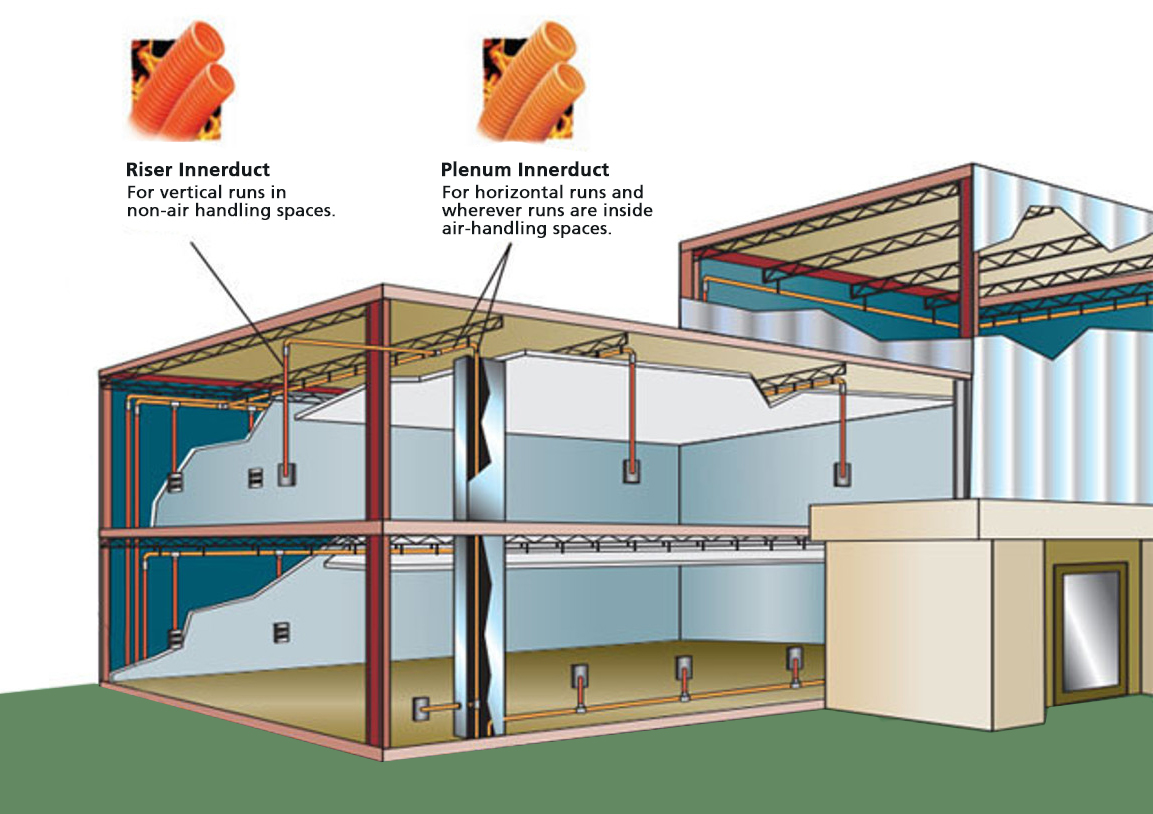

When using innerduct in a premises network, plenum-rated innerduct is required for air-handling spaces, such as above a dropped ceiling or under a raised floor. Riser-rated innerduct is deployed in shafts or pathways that traverse vertically between floors. Per the National Electric Code® (NEC®), plenum-rated innerduct must meet UL-2024 standards for low smoke and flame propagation, while riser-rated innerduct must meet UL-1666 standards for flame propagation.

When using innerduct in a premises network, plenum-rated innerduct is required for air-handling spaces, such as above a dropped ceiling or under a raised floor. Riser-rated innerduct is deployed in shafts or pathways that traverse vertically between floors. Per the National Electric Code® (NEC®), plenum-rated innerduct must meet UL-2024 standards for low smoke and flame propagation, while riser-rated innerduct must meet UL-1666 standards for flame propagation.

While innerduct protects fiber optic cables installed throughout telecommunications spaces and pathways, it is also ideal for segregating and managing cables. The standard color for innerduct is orange, but using different colors can be extremely useful for identifying fiber used for various systems or networks that reside in the same pathway. For example, a hotel with a traditional switched fiber network for back-office and facilities management applications and a passive-optical network for guest services can segregate the two types of fiber using different colored innerduct.

Fiber innerduct typically comes on reels and is pulled through pathways. When installing innerduct, it's essential to ensure a smooth end and avoid any jagged edges that could catch on any obstacles. One way to do this is to tape the cut end of the innerduct with electrical tape. Innerduct that comes with sequential footage markings is also extremely useful in facilitating installation. It helps ensure proper length for each run and lets you know how much innerduct remains on the reel.

Once innerduct is installed, fiber cables are pulled through the innerduct. Innerduct with a pre-installed pull tape or line makes for easy cable installation. For difficult pulls, the innerduct can be pre-lubricated before cable installation by pulling a rag soaked in lubricant through the innerduct or coating the cable with lubricant as it enters the innerduct. However, when using lubricant to lower pulling tension, the lubricant must be compatible with fiber optic cable—using incompatible substances for lubrication, such as basic liquid detergent, can degrade the cable's outer jacket and lead to performance issues over time.

The good news is that CablesPlus offers plenum- and riser-rated innerduct in six different sizes and multiple colors with sequential marked footage and pre-installed pull tape to simplify your fiber innerduct installations. And our innerduct boxes and reels come in a variety of lengths for any size job—from as little as 50 feet to as much as 9000 feet.

As innerduct conduit experts, CablesPlus can help you determine the right innerduct size and fill ratio for your specific network installation. Contact us today for all your fiber innerduct needs.