Why Consistency Across Fiber Optic Components Matters

- Jul 24th 2025

Fiber optic connectivity is the foundation of the digital era. It transmits data within hyperscale, cloud, and enterprise data centers, and it serves as the high-speed backbone of the internet, connecting our homes, businesses, cities, and countries.

The performance and reliability of fiber optic networks are paramount for supporting today’s applications – from artificial intelligence and high-performance computing in the data center to financial transactions, medical imaging, video streaming, online gaming, and more. Consistency across the fiber optic components that comprise today’s networks plays an essential role.

Avoid Mixing Fiber Types

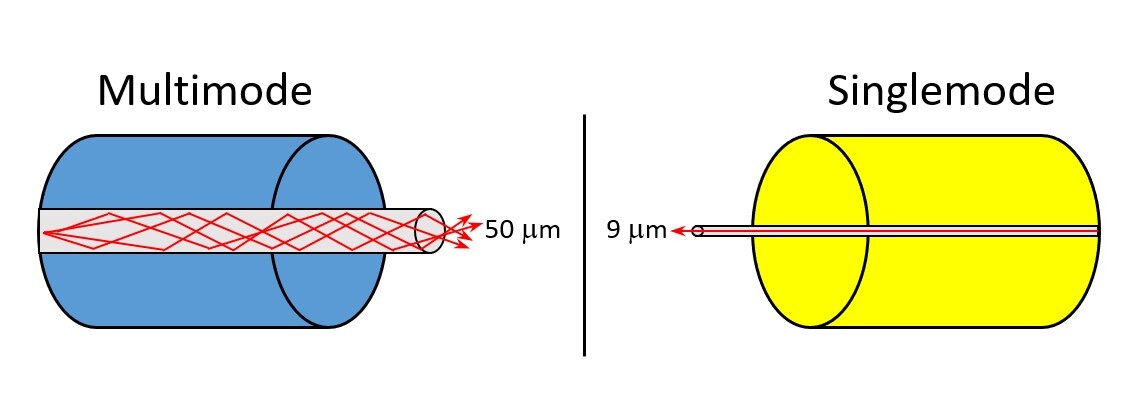

When it comes to fiber optic networks, the type of cables and connectors that comprise a fiber link must match to achieve optimal performance and reliability. First, multimode and singlemode fiber systems are not inherently compatible. In multimode fiber systems, transceivers transmit wide beams of light signals using low-power vertical-cavity surface-emitting lasers (VCSELS), typically at a wavelength of 850 nanometers (nm). These signals travel over multiple modes (paths) through the larger 50-micron (μm) or 62.5-μm core of a multimode fiber. In singlemode fiber systems, transceivers transmit a much narrower beam of light using higher-power edge-emitting lasers at wavelengths of either 1310 or 1550 nm. These narrow beams of light travel in a single mode (hence the name) through a much smaller 9-micron core, enabling much longer distances compared to multimode.

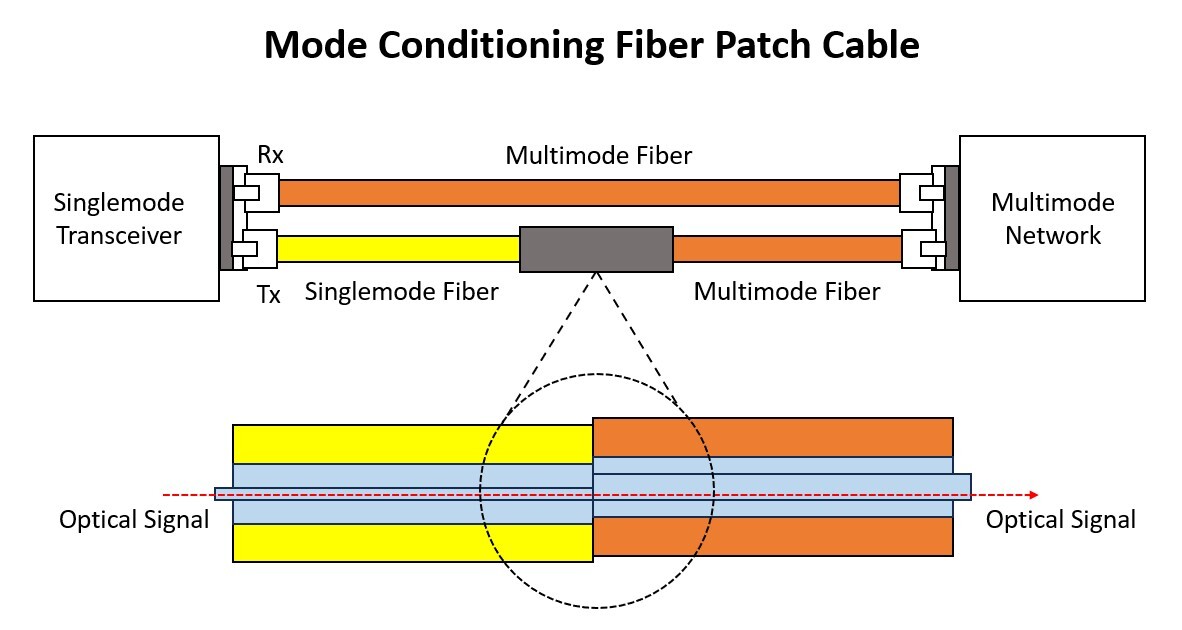

If multimode and singlemode fiber are directly connected, the difference in core size can cause so much signal loss that the connection will be unreliable at best, and likely won’t function at all. However, optical mode conditioning patch cables can be used to allow a singlemode transceiver to communicate with a multimode transceiver, which is ideal for connecting a legacy 62.5-μm n multimode network with external 10 Gigabit (1000Base-LX) singlemode transmission. These mode conditioning cables provide a method of offsetting a singlemode fiber core with a corresponding multimode fiber.

It is also important not to connect different performance levels of multimode fiber cable. When connecting different performance levels, the cable link will typically only perform to the lowest level, which can cause problems. For example, OM4 multimode cable supports 400 Gigabit transmission over distances of up to 100 meters, whereas OM3 multimode supports distances up to 70 meters. If your link has a mix of OM3 and OM4 and is longer than 70 meters, there is a good chance that the insertion loss will be too high for the application to function properly.

Cable color is one way to help avoid mixing different cable types in fiber networks. In fact, magenta was introduced for OM4 for this very purpose. The table below shows the various standards-based fiber cable colors. Note, however, that some military and specialty applications may use alternative colors.

|

Fiber Type |

Cable Color |

|

|

OM1 62.5μm Multimode |

Orange |

|

|

OM3 50μm Multimode |

Aqua |

|

|

OM4 50μm Multimode |

Aqua |

Magenta |

|

OM5 50μm Multimode |

Lime Green |

|

|

OS1/OS2 Singlemode |

Yellow |

|

Use Corresponding Connectors

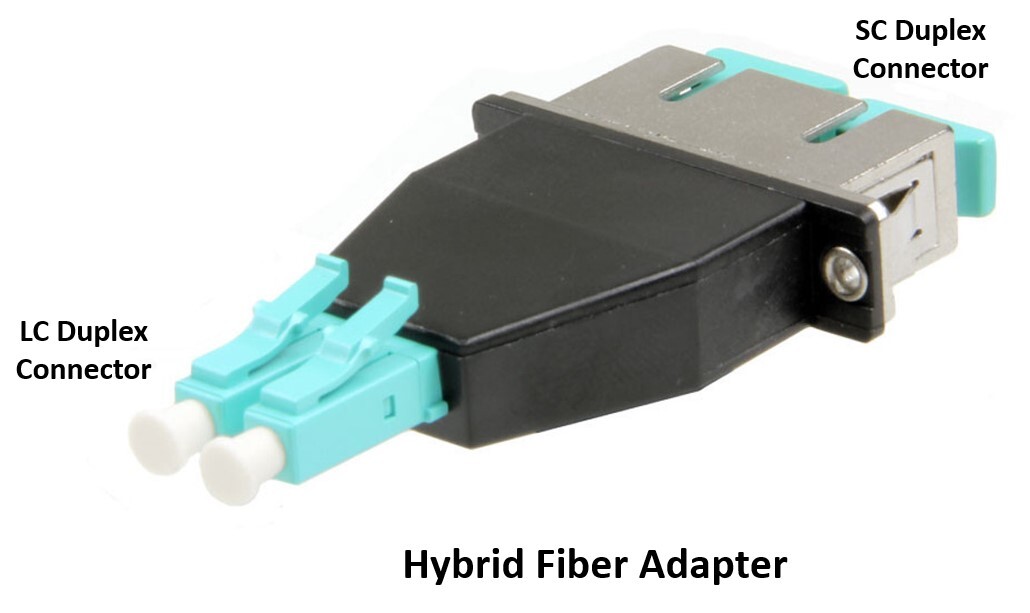

In addition to fiber type, connector type (MPO, LC, SC, ST, FC, etc.) should also match. Thankfully, form factors, alignment pins, and other features make it virtually impossible to directly connect diverse connector types. However, a hybrid adapter can be used to connect different types of connectors. They are available in a range of combinations and fiber types.

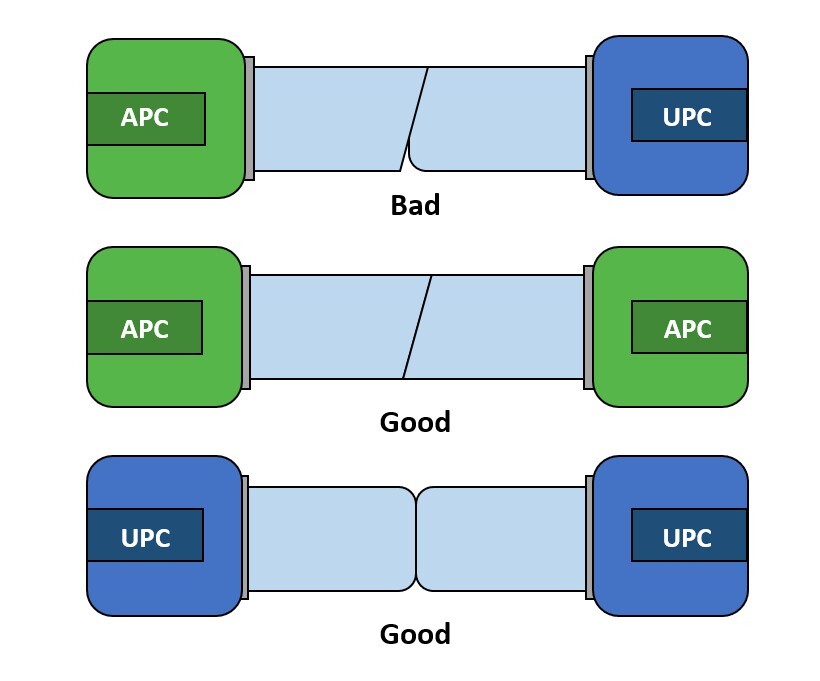

The geometry of the connectors should also match. Mating an APC (angled physical contact) connector end face that features an 8-degree angle with a UPC (ultra physical contact) connector that has no angle can cause damage to the fiber. To help avoid confusion between APC and UPC connectors, APC connectors feature a green housing, while UPC connectors feature a blue housing.

Standards and Quality Count

While compatibility between fiber types and connector types is crucial for ensuring optimal performance and reliability in fiber networks, standards compliance and consistent quality are also important considerations when selecting components.

Industry standards for fiber and cable connectivity specify physical and mechanical design, contact and housing materials, and performance parameters. These standards ensure interoperability between components of the same type from different vendors, allowing any LC multimode fiber connector to mate with any other LC multimode fiber connector. Interoperability is essential for reliable and efficient communication within and between networks. It also increases flexibility and prevents costly proprietary vendor lock-in.

The following industry standards are vital for ensuring interoperability and performance in fiber optic networks:

- ANSI/TIA-568: Published by the Telecommunications Industry Association (TIA), the ANSI/TIA-568 series of commercial building cabling standards defines fiber cabling systems and performance. ANSI/TIA-568.3, in particular, specifies performance, transmission, and test and measurement requirements for fiber cable, connectors, connecting hardware, and patch cords.

- TIA/EIA-604: Published by TIA, TIA-604 is a Fiber Optic Connector Intermateability Standard (FOCIS) that specifies the physical attributes required to ensure that fiber optic connectors will mechanically intermate. Within this series of standards, each connector type has its own FOCIS.

- ISO/IEC 11801: Published by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), ISO/IEC 11801 is essentially the international version of ANSI/TIA-568.

- IEC 61754: This series of standards specifies interface dimensions for various types of fiber connectors, including LC (61754-20), SC (61754-4), and MPO connectors.

- IEC 60793: This series of standards covers uniform requirements for measuring and testing various types of optical fibers (OM3, OM4, OM5, OS1/OS2, etc.)

- IEC 60794: This series of standards covers generic requirements for the geometrical, transmission, material, mechanical, ageing (environmental exposure), climatic, and electrical properties of optical fiber cables.

- IEEE 802.3: Published by the Institute of Electrical and Electronics Engineers (IEEE), this series of standards defines the physical layer and media access control (MAC) requirements for various Ethernet applications.

- ITU-T G: This series of recommendations from the International Telecommunication Union (ITU-T) addresses the geometrical properties and transmission properties of multimode and singlemode fiber optic cables for telecommunications systems.

- Telcordia GR: This series of “general requirements” from Telcordia (the former R&D arm of the Bell operating companies) provides guidelines and specifications to ensure the reliability, safety, and performance of telecommunications equipment and components used in central offices, outside plant, and other network environments.

While correctly matching fiber and connector types and ensuring standards compliance significantly reduces the risk of encountering performance and reliability issues that can lead to network failures and costly downtime, quality cannot be overlooked. The fact is that not every fiber optic component is the same; some vendors manufacture their components with greater precision, superior materials, and quality control at every production stage. Consistent quality of fiber optic components is essential to ensure long-term network reliability and performance.

The good news is that Cables Plus is committed to providing only the highest quality fiber optic products and solutions that meet stringent industry standards. We’re also here to help you select the right fiber optic components and configurations for your specific needs, ensuring you avoid any risk of incompatibility and noncompliance.

Explore Our Complete Range of Fiber Optic Solutions Contact an Expert