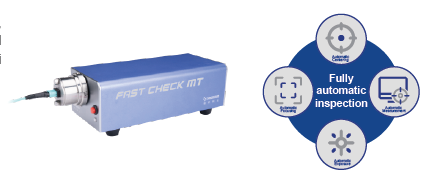

Fast Check MT Fully Fiber Endface Inspector

Product Overview

With the upsurge of artificial intelligence, digital reality, AI, etc., the demand for end -facial detection requirements such as 800G, 1.6T optical modules, MPO connectors and high -density connectors globally, and the efficiency of production detection

has continued to face challenges. In order to quickly improve the efficiency of the production detection of the end surface, Metropolitan Technology launched Fastcheck MT full -end surface detector. For multi -core optical modules and connectors, the range of the field is large enough to detect all the optical fibers of the multi -core surface at one time. It is more convenient to use automatic use. Automatic focusing, automatic finding center, and automatic detection can quickly improve the detection efficiency. At the same time, it stores pictures and reports to facilitate production traceability. With an independent I/O interface, it can become an automated detection and cleaning solution with the OFFSOON PRO cleaning unit, becoming an ideal choice for automated production lines.

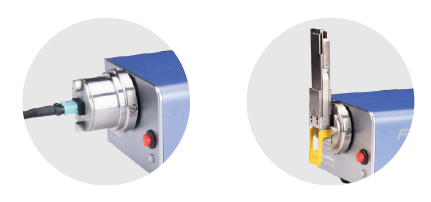

- MPO/PC connector adapter

- MPO/APC connector adapter

- MPO/PC module elbow adapter

- MPO/APC module elbow adapter

Optional Adapters

Main Features

- Fully Fiber Endface Pass/Fail inspection at one time.

- Full automatic detection, high efficiency, measurement speed for about 5 seconds.

- Compatible with a variety of MT connector types and transceivers inspection.

- Software interface is user-friendly.

- Combined with Offsoon Pro cleaning unit to set up a fully automated production line.

Applications

- 400G/800G/1.6T and other light module manufacturing

- MT/MPO/MMC/SN-MT equal multi-core connector manufacturing inspection

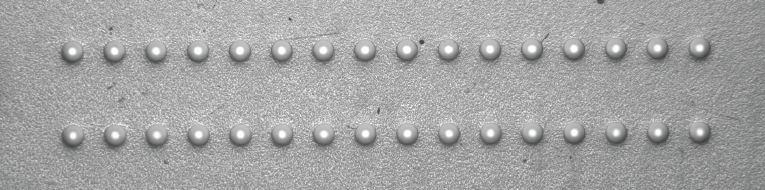

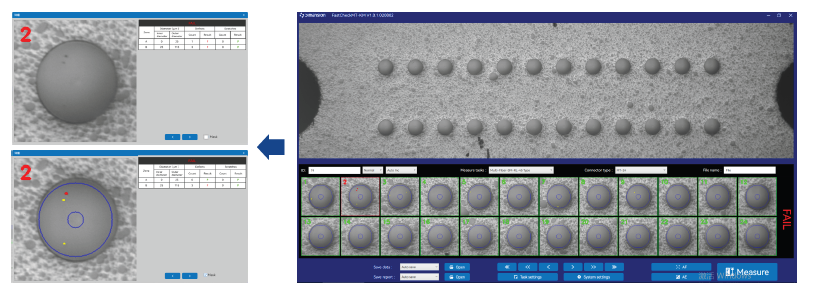

Fully Automatic Fiber Endface detection at one time

Fastcheck MT, its hardware adopts a large field of view camera and optical path system. Thanks to the large field of view it can realize a fast inspection on multifiber at a time which effectively improves the production efficiency.

Automatic Pass/Fail analysis, high efficiency

Automatic focusing, automatic finding center, automatic exposure, automatic inspection, reducing manual operations, and reducing dependence on operators. The test speed is about 5s.

Compatible with a variety of MT connector types and module detection

A variety of light modules such as 400G/800G/1.6T and MT/MPO/MMC/SN-MT and other multi-core connectors can be detected.

Software interface is user-friendly

Comprehensive I/O interface

FastCheck MT has an independent I/O interface, which can achieve remote trigger measurement and transmission

measurement results; it can realize the linkage with other devices.

Strong extension function

The FastCheck MT can be used in conjunction with the Offsoon Pro to set up a fully automated cleaning and inspection system for multifiber connectors and transceivers.