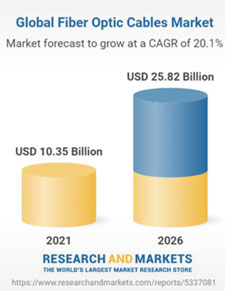

With emerging technologies like high-definition 4K video streaming, online gaming, IoT, virtual reality, artificial intelligence, 5G, and others requiring the transmission of more data at faster speeds, fiber optic cabling infrastructure has become the de facto standard for backbone switch-to-switch links in data center, LAN, campus, and outside plant environments. The bandwidth, distance, and ease of installation due to its lighter weight and smaller diameter are also driving more fiber in horizontal infrastructure to connect servers in the data center and edge devices in LANs. It's no wonder that recent reports estimate the global fiber optic cable market to reach more than $25 billion in the next five years at a compound annual growth rate of nearly 20%.

With emerging technologies like high-definition 4K video streaming, online gaming, IoT, virtual reality, artificial intelligence, 5G, and others requiring the transmission of more data at faster speeds, fiber optic cabling infrastructure has become the de facto standard for backbone switch-to-switch links in data center, LAN, campus, and outside plant environments. The bandwidth, distance, and ease of installation due to its lighter weight and smaller diameter are also driving more fiber in horizontal infrastructure to connect servers in the data center and edge devices in LANs. It's no wonder that recent reports estimate the global fiber optic cable market to reach more than $25 billion in the next five years at a compound annual growth rate of nearly 20%.

But when it comes to selecting the right fiber optic cable for your environment, there are several key considerations and a variety of attributes to choose from, ranging from type of fiber and strand count to construction and application. Let's look at some of these attributes to help you make the right selection.

- Pick Your Fiber Glass Type & Color

- Know Your Fiber Strand Count

- Choose the Right Fiber Construction for Your Environment

- Understand the Fiber Requirements of Your Application

Pick Your Fiber Glass Type & Color

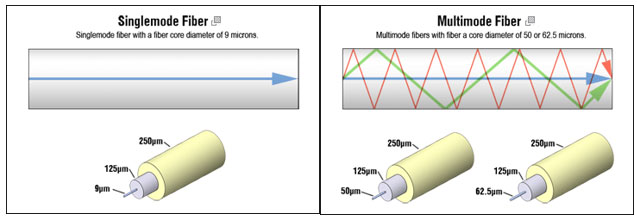

First, you need to choose your glass type—either singlemode or multimode.

Singlemode fiber features a smaller-diameter glass core and uses high-power laser transceivers primarily at 1310 and 1550 nanometer (nm) wavelengths. In general, singlemode fiber supports higher bandwidth and longer distances, which is why it's used in outside plant long-haul and campus networks and in-building LAN backbones. Singlemode fiber supports distances up to 40 kilometers, and for high-speed transmission above 10 Gigabits per second (Gb/s), it is typically required for links longer than about 100 meters. Because of its bandwidth capabilities, singlemode is also often deployed in backbone data center switch links.

Multimode fiber on the other hand features a larger core and uses LED or lower-cost vertical-cavity surface-emitting (VCSEL) transceivers, typically at the 850 nm wavelength. While singlemode fiber is available in OS1/OS2, multimode fiber has advanced over the years from legacy OM1 with a core diameter of 62.5 microns (used with LED light sources) to OM3, OM4, and OM5 laser-optimized fiber with a 50-micron core diameter (used with VCSELs). The main difference in these types of multimode fiber is bandwidth and reach. For example, OM1 fiber can support 10 Gigabits per second to 33 meters, while OM3 reaches 300 meters and OM4 and OM5 reach 400 meters. OM5, also referred to as wide-band multimode, has the same bandwidth as OM4 at 850 nm, but has been optimized for performance at 953 nm to support the use of multiple wavelengths. In our next blog, we'll delve more into the technical differences between singlemode and multimode.

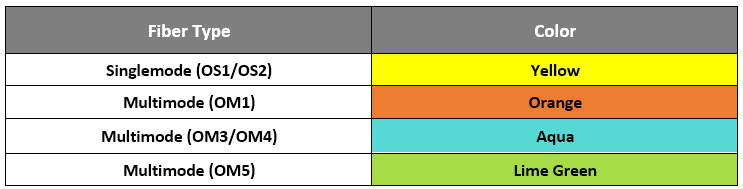

Per industry standards, different types of fiber also feature their own jacket colors as shown in the table below. This is primarily for ease of identification and to prevent accidental mixing and matching of fiber types—due to their different core sizes, singlemode and multimode can not be mixed and OM1 multimode can not be mixed with OM3, OM4, or OM5 multimode. While industry standards specify aqua for OM3/OM4, to more easily distinguish between the two, OM4 multimode is also often available in Erika Violet.

Know Your Fiber Strand Count

Fiber cable is available in a variety of strand counts with selection depending on the application and the number of connections. While there are high-count fibers available for specialty applications, most bulk fiber comes in strand counts of 2, 4, 6, 12, 18, 24, 36, 48, 72, and 144. One of the most commonly used fiber counts is a duplex (2) fiber cable used for a single duplex link where data transmits over one fiber and receives over another.

For backbone deployments, either in the LAN, campus, or outside plant environment, strand count depends on how many connections are needed to connect buildings and spaces and the amount of redundancy required. For in-building LAN backbones, it's common to need fiber counts of 24 or less, while campus and outside plant deployments may need higher counts. Strand count also sometimes depends on the application. For example, high-speed parallel optics applications where data is transmitted over multiple fibers include 8-fiber applications such as 40GBASE-SR4, 100GBASE-SR4, 200GBASE-SR4, and 400GBASE-SR4 multimode applications that transmit over 4 fibers and receive over 4 fibers at 10, 25, 50, and 100 Gb/s using multi-fiber push-on MPO connectivity (i.e., MTP). For these applications, it's common to see fiber counts of 24, 48, 72, and 144 that can break out to multiple 8-fiber MTP connectors.

Choose the Right Fiber Construction for Your Environment

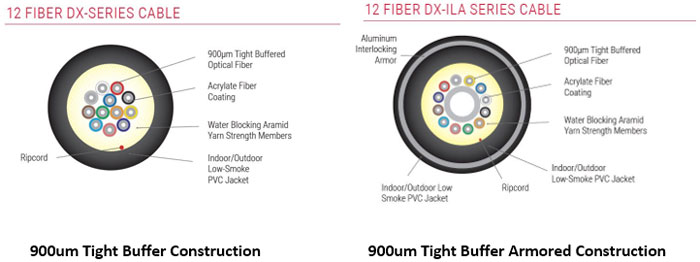

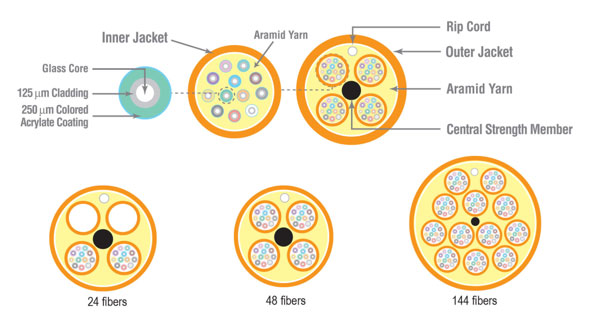

Fiber optic cable comes in two constructions—tight-buffered and loose tube. Tight-buffered cables feature a 900-micron protective layer over the 250-micron fibers, which are surrounded with aramid yarn. These cables may be constructed as breakout cables where each fiber has its own outer jacket, allowing them to be broken out for separate connections to devices. Tight-buffered cables may also be constructed as distribution cables where the fibers are bundled in a single outer jacket, resulting in a smaller, lighter-weight cable that's ideal for LAN backbones. Indoor applications almost always use tight-buffered cables. However, they are also available in indoor/outdoor versions that can transverse between buildings and feature some form of water blocking to prevent ingress. One type of tight-buffered cable is a duplex zip-cord cable. It features two individually jacketed fibers joined together, allowing them to be easily pulled apart for use as patch cables and in short interconnects.

250um Loose Tube Constructions (Data Center & Long Distance Applications)

In contrast, loose-tube cables are bare 250-micron (or 200-micron) fibers housed inside a plastic tube and primarily used for outside plant environments where the cable features water-blocking technology. Because they don't have the 900-micron protective layer found in tight-buffered cables, loose-tube cables have an overall smaller cable diameter.

Fiber cables may also feature armor for harsh environments such as outside plants or industrial applications. One type of armor is corrugated steel tape (CST) where steel tape wraps around the cable, making it a very rigid and rodent-proof cable. The other armor type is interlocking armor (ILA), which is much more flexible and rodent-resistant. CST tends to be for outside plant environments, while ILA is used more for harsh indoor environments.

When it comes to cable jackets, outside-plant environments require an outside-plant-rated jacket such as polyethylene (PE) which is good at moisture and overall weather resistance. For inside environments, cable jackets are either plenum (CMP) or riser (CMR) rated per UL. The main difference between plenum and riser ratings has to do with flame retardance—plenum cables feature a higher fire rating as required in plenum spaces (i.e., above drop ceilings or below raised floors), while riser-rated cables reside in vertical spaces between floors.

Understand the Fiber Requirements of Your Application

There is no "one-size-fits-all" when it comes to choosing a fiber cable, but it often comes down to application. While the application is frequently related to the environment, some have specific requirements. For example, military applications typically dictate that the fiber optic cable be MIL-SPEC, which means it meets certain military (defense) specifications for operating temperature, impact resistance, and other characteristics. Broadcasting installations (i.e., stadiums, arenas, video-on-demand) often require broadcast-rated fiber cables that are designed for flexibility and crush resistance to withstand crowd and vehicle traffic. Other applications such as mining or direct buried outside plant cables frequently require armored cables.

The good news is that the CablesPlus USA website offers the ability to filter results based on fiber cable type, strand count, color, environment, construction, jacket rating, and application. This simplified search capability with easy checkboxes lets you drill down to choose the right fiber optic cable for your project. And if you'd like to talk through your specific application for guidance in choosing the right cable, we can do that too! just contact us at sales@cablesplususa.com or 866-678-5852.