When deploying fiber links in data centers, LANs, or even in outside plant networks, fiber is pulled between equipment and spaces through pathways, cable managers, cable tray, risers, or conduit. While it may seem like a routine task, failure to pull properly can damage the cable in a way that prevents data transmission or impacts network performance over time. At the same time, the process of pulling fiber cable needs to be quick and efficient to get networks up and running faster. Let’s take a look at some of the key considerations and technologies needed to ensure performance and facilitate the process.

Key Specs to Consider

Know your lengths based on the network design

When using spooled fiber and field termination, installers need to ensure that fiber spools contain enough cable to accommodate the lengths. For preterminated fiber assemblies deployed in data center environments between and within racks, ordering the right lengths for fiber assemblies is essential. If the assemblies are too short and need to be reordered, you risk waste, delaying deployment, and racking up unnecessary costs. If they are too long, you’re left having to manage and store excess slack, which takes more time and may require the added cost of slack storage enclosures, trays, or other accessories. Once you have the right lengths, there are some key specifications to consider for pulling fiber cable.

Tensile Load

For any fiber cable, the tensile load is the maximum amount of pulling force that can be placed on the cable without causing any damage to the fibers or altering optical performance. Typically measured in pounds per square inch (lbs./in 2) or in Newtons (N), tensile load varies based on the type of cable and the number of fibers in the cable. Maximum tensile loads are specified by manufacturers and included in product documentation often as two different values—tensile load for installation and tensile load for operation. Tensile load for installation is the maximum amount of force allowed during the actual process of pulling cable. Tensile load for operation is the maximum amount of force that can remain on the cable once it’s installed and ready for operation. Tensile loads for installation are much higher than for operation because the force is short term. For example, our 12-strand tight buffered OM4 multimode cable has a installation tensile load of 1400 N (310 lbs.) and an operational tensile load of just 450 N (100 lbs.)

Tension

In general, fiber cables should be pulled with the least amount of tension in a steady, continuous motion to avoid exceeding the load. One common mistake is pulling fiber cable with tension only on the outer jacket of the cable, which is prone to stretching and can ultimately lead to tears or breaks in the jacket. Ideally, the tension should be placed on the aramid fiber yarns inside the jacket that surround the individual fibers. This is often achieved by connecting a cable pulling eye to the fiber yarns that are exposed using a fiber cable stripper that removes a small portion of the jacket.

Maximum Bend Radius

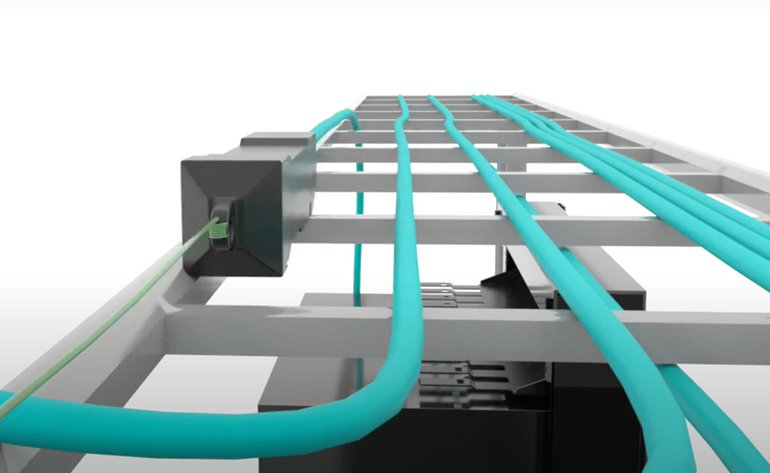

Another key specification is the maximum bend radius, which is dependent on the overall cable diameter—smaller cables have a smaller maximum bend radius and larger cables have a larger maximum bend radius. Exceeding the bend radius of a fiber cable can alter the optical characteristics of the fiber and cause the glass to crack over time. Like tensile load, maximum bend radius is also specified by the manufacturer and divided into the maximum bend radius during installation (i.e., under tension) and maximum bend radius during operation (i.e., long-term). For most fiber cables, the maximum bend radius is 20 times the diameter under tension and 10 times the diameter for long-term operation. Some fiber cables are designed to be bend-insensitive and may allow a smaller maximum bend radius of 15 times the diameter under tension. The good news is that fiber cable managers, raceway, and protection systems are designed to maintain proper bend radius.

While tensile load and bend radius are the primary specs to consider when pulling fiber, there are others to be aware of. Fiber cables also come with a specified installation temperature, storage temperature, and operation temperature range. They may also have a specified vertical rise, which specifies the maximum length a cable can be installed vertically whereby the weight of the cable will not exceed the operational tensile load. Fiber cables will also typically have a crush resistance and impact resistance specification, which determines the ability of a cable to withstand and recover from the effects of compression caused by weight and impact.

Pulling Pre-Term Assemblies

Pre-terminated fiber assemblies that are commonly deployed in the data center environment often come with an integrated pulling eye to facilitate pulling and avoid having to install your own pulling eye. These pulling eyes need to be properly integrated by the manufacturer to prevent too much force on the jacket and eliminate any force from being placed on the fibers.

One of the biggest problems with pulling eyes is that once an assembly is in place, the pulling eye needs to be removed before the connector can be plugged into the back of a cassette or adapter in a fiber patch panel. This involves carefully cutting off the leading end of the pulling eye, cutting off the sleeve, removing any tape installed around fibers and connectors, and cutting off excess strength members that emerge from the cable. This process can take upwards of 5 minutes per pulling eye, so for projects where you’re installing hundreds or even thousands of preterminated assemblies, labor and waste can really add up. Furthermore, the process significantly increases the risk of damaging the fiber such as accidently cutting the fiber, kinking the fiber, or exceeding bend radius. There is also the time required to separately mount the cassettes or adapters in the fiber patch panel in the first place.

One solution to eliminating problems associated with typical pulling eyes is the HD8² High Density Fiber Solution featuring HD8² HDReadyLink® and HDReadyPull® assemblies. These cassette-to-cassette and cassette-to-fanout assemblies integrate the cable and cassette in a single component. They feature a snap-on protective cap that doubles as an easily removable pulling eye once the cassette is snapped into the chassis, eliminating the need to install and plug together separate components, remove pulling eyes, risk fiber damage, and deal with loose cassettes and excessive waste. Rather than traditional wide, flat cassettes that may be too big to route through pathways, the HD8² cassettes feature a unique square design that provides greater density while also being small enough to easily route through pathways.

And to prevent exceeding tensile load and damaging the cable, the fiber terminates directly to the connectors within the HD8² cassette while the internal strength members are connected to an integrated strain relief, supporting about a 50-lb. pull force with no strain on the fibers themselves.

The good news is that Cables Plus has the pulling specs available for all of our fiber cable products and we offer a complete range of OM3, OM4, and OM5 multimode and singlemode HD8² HDReadyLink® and HDReadyPull® assemblies with MTP, LC, MDC, and CS connectors. Just contact us at sales@cablesplususa.com or 866-678-5852 for more information.