Which Fiber Termination Method is Right for You?

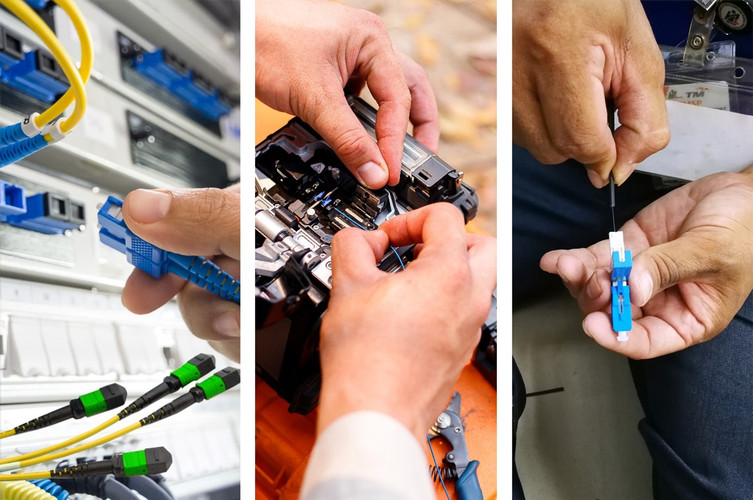

Fiber optic cabling can be pre-terminated to connectors by your cabling supplier, or they can be terminated in the field using fusion splicing with pigtails or splice-on connectors or using mechanical splice or traditional epoxy/polish connectors.

With an increasing number of fiber links in LANs and data centers, designers and installers need to determine which termination method is best for their project. Several different factors can influence that decision, including application, environment, number of terminations, performance, budget, schedule, level of expertise, and available tools. Let’s take a closer look at the options and key considerations for each.

,

The Labor-savings Pre-term

Pre-terminated fiber assemblies are available in multiple fiber types, counts, and connector interfaces. They can be multimode or singlemode and terminated with duplex connectors, like LCs, or with multi-fiber push-on (MPO/MTP®) connectors. They are also available in breakout cables that are pre-terminated with MPO/MTP®’s on one end and with multiple duplex connectors on the other end for making connections from MPO/MTP® trunk cables to duplex equipment or for supporting breakout applications, such as breaking out a 400 Gig switch port to four 100 Gig connections. Fiber patch cords are one type of assembly that is virtually always pre-terminated, since they are used for efficient patching between equipment and patch panels. But when it comes to backbone fiber links in LANs and data centers, pre-terminated assemblies may or may not be the best choice.

Pre-terminated assemblies offer the benefit of quick

plug-and-play installation with no specific fiber termination skill required, no consumables, and little waste. They also offer superior performance due to factory termination with less variability and minimal risk of contamination. While labor is significantly reduced with pre-term assemblies and no tools are required, they do carry the highest material cost and can require longer lead times for custom lengths. With pre-terminated assemblies, lengths must also be carefully predetermined before ordering—if the assembly is too short, installation will be delayed, and a new assembly will need to be ordered at an additional cost. However, if you carefully plan your lengths and can support the longer lead time, the labor savings of pre-terminated fiber may outweigh the higher material cost depending on the number of links. In addition to predetermining lengths, it’s also important to order the right polarity method and gender for pre-terminated MPO/MTP® assemblies, or make sure to choose connectors like the MTP Elite Pro that lets you change polarity and gender in the field .

When it comes to choosing pre-term fiber, there are some additional considerations. There are some applications that are simply more suited to this termination method. Parallel optic applications like 8-fiber 40, 100, 200, and 400 Gigabit applications used in high-density data center backbone switch links use MPO/MTP® connectors with four fibers transmitting and four receiving at either 10, 25, 50, or 100 Gigabits per second. MPO/MTP® connectors are usually pre-terminated because they can’t be effectively terminated in the field using a mechanical splice or epoxy/polish connector. For scenarios where lengths can’t be predetermined, or in a disaster recovery situation where longer lead times are not an option, MPO/MTP®’s can be spliced using splice-on pigtails or connectors as described below.

The Low-Loss Splice

Fusion splicing is the process of fusing fibers together

with an electronic arc, creating a strong, reliable, and lowest-loss connection. This is achieved using a fiber splicer that aligns and fuses two cleaved fibers. For multi-fiber applications, a mass fusion splicer can fuse multiple fibers at once. Splicing can be done using pigtails, which are short stubs of bare fiber that are pre-terminated on one end, leaving the other end exposed for splicing. When using pigtails, the splices need to be protected in splice protection sleeves and stored in splice trays that are typically housed in splice enclosures . Splicing can also be done with splice-on connectors. While splice-on connectors also require a fiber splicing machine, they don’t require protection sleeves and splice storage because the stub resides and is protected within the connector itself. Splicing can also be used on two bare fibers for making repairs, such as a broken fiber, especially since it is the lowest loss option and less apt to impact performance of existing links.

The decision to splice or not to splice has a lot to with the application. As previously mentioned, splicing is the only option for field termination of MPO/MTP® connectors. Splicing is also the best option for transitioning from 250-micron loose tube outside plant fiber to 900-micron tight-buffered indoor distribution fiber. That is why splicing is exclusively used at the building entrance or demarcation for terminating incoming service provider fiber. While a good fusion splicer and cleaver will run around $5,000, with mass fusion splicers typically more than twice that cost, it’s well worth the investment if you do a lot of building entrance terminations

The Always-Popular Mechanical

Duplex and simplex mechanical splice connectors are an extremely popular low-cost termination method that aligns and joins fibers together with integrated index matching gel. This gel has an index of refraction that closely matches that of the fiber cores to limit reflection or refraction of the light signal.

While a mechanical splice is not as low loss as a fusion splice, it is considered a reliable and fast termination method for most duplex applications. Mechanical splice connectors are typically a vendor-specific system with an accompanying installation tool, like the well-known Corning UniCam® connectors. While there is a slight learning curve to master properly stripping and cleaving the fiber in preparation for termination, most mechanical splice connectors are easy to terminate. The quality of a mechanical splice termination is easily verified with a visual fault locator (VFL) that checks for continuity, with some mechanical termination tools featuring an integrated VFL.

Once an installer invests in a mechanical splice termination kit, it is considered one of the fastest, easiest, and low-cost termination methods for duplex fiber applications that don’t have stringent insertion loss budgets of less than 0.2 dB per connector. It’s especially cost-effective for low-count fiber installations such as backbone LAN cabling and fiber-to-the-desk (FTTD) applications. They are also ideal for fast deployments, repairs, and reconfiguration. But remember, mechanical splice connectors aren’t an option for MPO/MTP®’s.

The Traditional Epoxy Option

The last option for terminating fiber are traditional epoxy/polish-type connectors. These connectors require carefully cleaving, polishing, and cleaning the fiber endface. They can be epoxy-type connectors that are heat cured in a cure oven, which takes about anywhere from 15 to 30 minutes.Or these traditional connectors can be quick-cure anaerobic connectors that use an adhesive with a primer that hardens the adhesive in about a minute. Epoxy termination kits are available with all the tools and consumables needed to terminate traditional connectors, however consumables like polishing paper,epoxy, and tools need to be continually replenished.

While traditional connectors are inexpensive and can achieve a similar loss performance to mechanical splice connectors, the performance of this termination method has a lot to do with skill level and experience. These connectors are more prone to contamination and the cleave, polish, and cleaning must be precise, or the connector could exhibit a much higher loss. However, for technicians who are skilled and comfortable, traditional epoxy/polish connectors remain popular and effective. Like mechanical splice connectors, tradition epoxy/polish connectors are also best for lower-count deployments, and the aerobic-cure connectors are ideal for fast deployments or repairs.

Summing It All Up

Now that we’ve covered each of the fiber termination methods, let’s summarize your option based on key decision factors. This handy chart below is a good place to start when determining which fiber termination method is right for you. You can also check out our Termination Kit Video for more information.

The good news is that as part of our comprehensive line of fiber optic solutions , Cables Plus offers everything you need for pre-terminated, splicing, mechanical-splice, and traditional fiber termination—from cable assemblies and splicers, to connectors, termination tools, and consumables. And if you’re still not sure which termination method to choose for your specific project, just contact us at sales@cablesplususa.com or 866-678-5852 and we’d be happy to help!