-

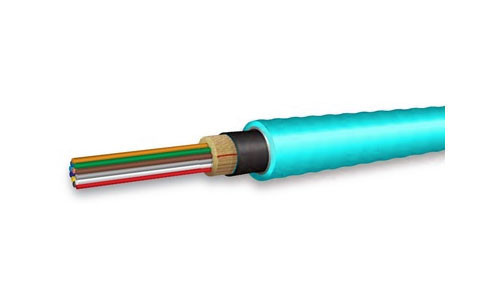

OCC, DX, 12-Strand, Armored & OM3 laser-optimized multimode fiber OFNP, OM3, Aqua (Priced Per Foot)OCC, DX, Distribution Series, 12-Strand, 900um Tight Buffered, Indoor/Outdoor, ILA Armored, OFNP Plenum Rated, OM3, 50/125, Multimode, Aqua Jacket Reference Previous Part Number: DX12-060K-ALT/900-OFCP-IAK Note: This item may require 24 hours for cut and...$3.41$3.08

OCC, DX, 12-Strand, Armored & OM3 laser-optimized multimode fiber OFNP, OM3, Aqua (Priced Per Foot)OCC, DX, Distribution Series, 12-Strand, 900um Tight Buffered, Indoor/Outdoor, ILA Armored, OFNP Plenum Rated, OM3, 50/125, Multimode, Aqua Jacket Reference Previous Part Number: DX12-060K-ALT/900-OFCP-IAK Note: This item may require 24 hours for cut and...$3.41$3.08 -

OCC, DX Series, 12-Strand, PVC Armored with Plenum Jacket, OS2, SM, Yellow (Priced Per Foot)OCC, DX, Distribution Series, 12-Strand, 900um Tight Buffered, Indoor/Outdoor, ILA Armored, OFNP Plenum Rated, OS2, 9/125, Singlemode, Yellow Jacket Installation zone RECOMMENDATION Ideal for industrial and other installations requiring a metallic...$3.12$2.82

OCC, DX Series, 12-Strand, PVC Armored with Plenum Jacket, OS2, SM, Yellow (Priced Per Foot)OCC, DX, Distribution Series, 12-Strand, 900um Tight Buffered, Indoor/Outdoor, ILA Armored, OFNP Plenum Rated, OS2, 9/125, Singlemode, Yellow Jacket Installation zone RECOMMENDATION Ideal for industrial and other installations requiring a metallic...$3.12$2.82 -

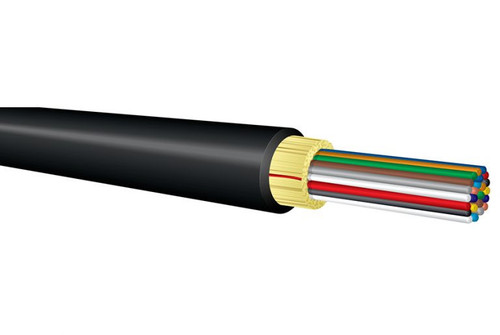

OCC DX Series 24 Fiber Singlemode Bend Insensitive Indoor/Outdoor Rise, Black JacketOCC, DX, Distribution Series, 24-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNR Rated, OS2, 9/125, Bend Insensitive Singlemode, Black Jacket Note: This item may require 24 hours for cut and prep before shipping. DX-Series Distribution – Riser...$1.60$1.44

OCC DX Series 24 Fiber Singlemode Bend Insensitive Indoor/Outdoor Rise, Black JacketOCC, DX, Distribution Series, 24-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNR Rated, OS2, 9/125, Bend Insensitive Singlemode, Black Jacket Note: This item may require 24 hours for cut and prep before shipping. DX-Series Distribution – Riser...$1.60$1.44 -

OCC, DX, Distribution Series, 4-Strand, 900um Tight Buffered, Indoor/Outdoor, Chemical Resistant OFNP Plenum Rated, 9/125, Singlemode Bend Tolerant Ultra-Fox™ (Priced Per Foot)Bulk Fiber, 4 Strand, Singlemode, 9/125, OS2, OFNP Plenum Rated, Indoor/Outdoor, Yellow Outer Jacket This plenum distribution fiber cable is used in trunking, LAN and distribution applications where small size, lightweight, and versatile installation...$1.39$1.26

OCC, DX, Distribution Series, 4-Strand, 900um Tight Buffered, Indoor/Outdoor, Chemical Resistant OFNP Plenum Rated, 9/125, Singlemode Bend Tolerant Ultra-Fox™ (Priced Per Foot)Bulk Fiber, 4 Strand, Singlemode, 9/125, OS2, OFNP Plenum Rated, Indoor/Outdoor, Yellow Outer Jacket This plenum distribution fiber cable is used in trunking, LAN and distribution applications where small size, lightweight, and versatile installation...$1.39$1.26 -

OCC, Distribution 6 Fiber Singlemode Bend Tolerant Ultra-Fox Plenum Black JacketDZ-Series – Riser Rated Cables Part Number: DZ006TSLA9KP OCC, DZ, Distribution Series, 6-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM4, 50/125, Multimode, Black Jacket Offering the durability you expect from OCC, these...$0.48$0.44

OCC, Distribution 6 Fiber Singlemode Bend Tolerant Ultra-Fox Plenum Black JacketDZ-Series – Riser Rated Cables Part Number: DZ006TSLA9KP OCC, DZ, Distribution Series, 6-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM4, 50/125, Multimode, Black Jacket Offering the durability you expect from OCC, these...$0.48$0.44 -

OCC DX Series 48 Fiber Singlemode Bend Insensitive Indoor/Outdoor Riser, Black JacketDX-Series Distribution – Riser Rated Cables Indoor/Outdoor tight-buffered design allows cables to be installed in intra-building backbone and inter-building campus locations without costly transitions between cable types Ideal configuration for...$3.34$3.02

OCC DX Series 48 Fiber Singlemode Bend Insensitive Indoor/Outdoor Riser, Black JacketDX-Series Distribution – Riser Rated Cables Indoor/Outdoor tight-buffered design allows cables to be installed in intra-building backbone and inter-building campus locations without costly transitions between cable types Ideal configuration for...$3.34$3.02 -

Distribution 12 Fiber Singlemode Bend Tolerant Ultra-Fox™ Indoor/Outdoor Riser Black Jacket (Priced Per Foot)DZ-Series – Riser Rated Cables Installation zone RECOMMENDATION Offering the durability you expect from OCC, these distribution cables provide all of the indispensable elements needed for Indoor and Indoor/Outdoor commercial applications, while...$0.73$0.66

Distribution 12 Fiber Singlemode Bend Tolerant Ultra-Fox™ Indoor/Outdoor Riser Black Jacket (Priced Per Foot)DZ-Series – Riser Rated Cables Installation zone RECOMMENDATION Offering the durability you expect from OCC, these distribution cables provide all of the indispensable elements needed for Indoor and Indoor/Outdoor commercial applications, while...$0.73$0.66 -

OCC DX Series 2 Fiber Singlemode Bend Insensitive Indoor/Outdoor Rise, Black JacketOCC, DX, Distribution Series, 2-Strand, 900um Tight Buffered, Indoor/Outdoor,OFNR Rated, OS2, 9/125, Singlemode, Black JacketReference Previous Part Number: DX02-045D-SLX/900-OFNR Note: This item may require 24 hours for cut and prep before shipping...$0.33$0.30

OCC DX Series 2 Fiber Singlemode Bend Insensitive Indoor/Outdoor Rise, Black JacketOCC, DX, Distribution Series, 2-Strand, 900um Tight Buffered, Indoor/Outdoor,OFNR Rated, OS2, 9/125, Singlemode, Black JacketReference Previous Part Number: DX02-045D-SLX/900-OFNR Note: This item may require 24 hours for cut and prep before shipping...$0.33$0.30 -

OCC, DX, Distribution Series, 24-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM3, 50/125, Multimode, Aqua Jacket (Priced Per Foot)OCC, DX, Distribution Series, 24-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM3, 50/125, Multimode, Aqua JacketReference Previous Part Number: DX24-075K-ALT/900-OFNP Note: This item may require 24 hours for cut and prep before...$1.29$1.17

OCC, DX, Distribution Series, 24-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM3, 50/125, Multimode, Aqua Jacket (Priced Per Foot)OCC, DX, Distribution Series, 24-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM3, 50/125, Multimode, Aqua JacketReference Previous Part Number: DX24-075K-ALT/900-OFNP Note: This item may require 24 hours for cut and prep before...$1.29$1.17 -

OCC, DX Series, 12-Strand, Tight Buffd, I/O, OFNR, OS2, SM, Black (Per Foot)DX-Series Distribution – Riser Rated Cables Installation zone RECOMMENDATION Indoor/Outdoor tight-buffered design allows cables to be installed in intra-building backbone and inter-building campus locations without costly transitions between...$0.90$0.81

OCC, DX Series, 12-Strand, Tight Buffd, I/O, OFNR, OS2, SM, Black (Per Foot)DX-Series Distribution – Riser Rated Cables Installation zone RECOMMENDATION Indoor/Outdoor tight-buffered design allows cables to be installed in intra-building backbone and inter-building campus locations without costly transitions between...$0.90$0.81 -

OCC, DZ Series, 6-Strand, 900um Tight Buff, I/O, OFNP, OM4, 50/125, Multimode, Aqua Jacket (Priced per Foot)OCC, DZ, Distribution Series, 6-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM4, 50/125, Multimode, Aqua Jacket Offering the durability you expect from OCC, these distribution cables provide all of the indispensable elements needed...$0.91$0.83

OCC, DZ Series, 6-Strand, 900um Tight Buff, I/O, OFNP, OM4, 50/125, Multimode, Aqua Jacket (Priced per Foot)OCC, DZ, Distribution Series, 6-Strand, 900um Tight Buffered, Indoor/Outdoor, OFNP Plenum Rated, OM4, 50/125, Multimode, Aqua Jacket Offering the durability you expect from OCC, these distribution cables provide all of the indispensable elements needed...$0.91$0.83 -

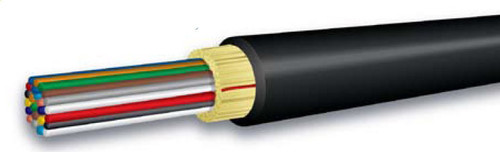

AFL, DX 12 Strand, 900um Tight Buffer, In/Out, PVC - Plenum, OS2, 9/125 SM, Corning® SMF-28® Ultra ITU G.652.D/G.657.A1, 6.1mm, Black Jacket (Priced Per Foot)AFL's KQ0124612801 fiber is a Singlemode Indoor/Outdoor Tight Buffer, PVC - Plenum Rated , 12 StrandCorning® SMF-28® Ultra ITU G.652.D / G.657.A1 fibers, 6.1 mm OD, RoHS, Standard Strip, Black Jacket Fiber cable. Overview: AFL...$0.63$0.57

AFL, DX 12 Strand, 900um Tight Buffer, In/Out, PVC - Plenum, OS2, 9/125 SM, Corning® SMF-28® Ultra ITU G.652.D/G.657.A1, 6.1mm, Black Jacket (Priced Per Foot)AFL's KQ0124612801 fiber is a Singlemode Indoor/Outdoor Tight Buffer, PVC - Plenum Rated , 12 StrandCorning® SMF-28® Ultra ITU G.652.D / G.657.A1 fibers, 6.1 mm OD, RoHS, Standard Strip, Black Jacket Fiber cable. Overview: AFL...$0.63$0.57