Optical Cable Corporation

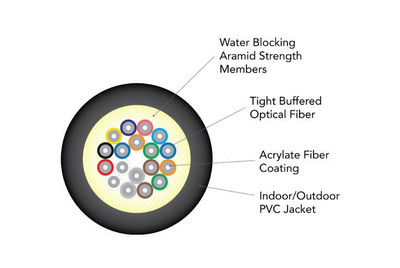

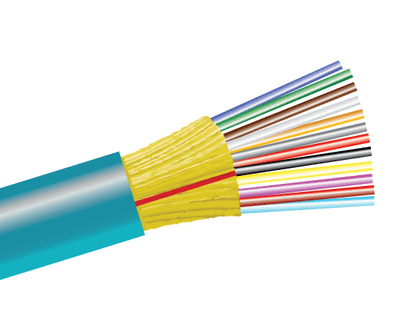

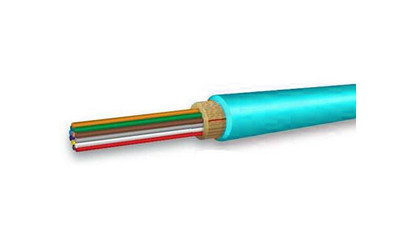

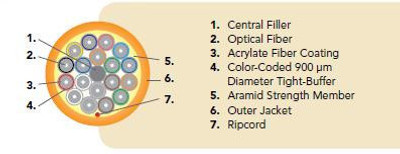

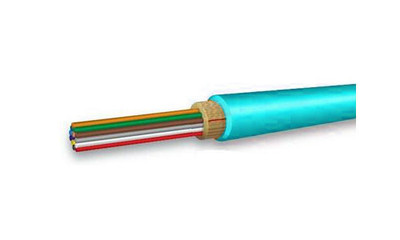

OCC, DX, T-Series, 12-Strand, 900um Tight Buff, I/O, OFNP, OM4, 50/125, Multimode, Aqua Jacket (Priced Per Foot)

List Price:

$2.36

$2.13