Speak to one of our experts.

BINNA2 is an automatic detection interface developed by Dimension Technology This device inherits the rich experience of Dimension Technology in interpreters for many years, and adds automatic focusing and automatic calibration functions on the basis of SANA2 It is the cultivation of single core interpreters&Nbsp; BINNA2 options a brand new software design, a brand new fixture platform structure, and fixture structure design, further enhancing the seismic resistance of the equipment&Nbsp; The service life and measurement stability of fixtures have also been unprecedentedly improved

Main Features

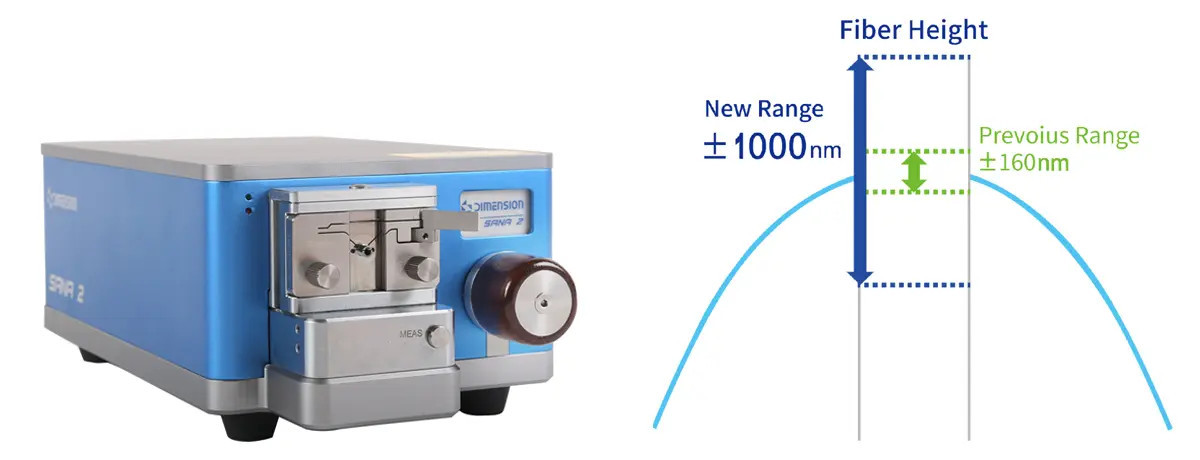

Fiber optical height reaches -1000-1000nm

Automatic angle adjustment

Auto focus, auto proofreading, one click measurement

0.5s; Complete individual connector testing

Strong seismic resistance

Automatic centering function of fixtures

BINNA2; The intermediary fixture attachments a brand new design, and there is no need to make any hardware adjustments after installation on the intermediary Simply click the "Image Center" button on the software interface, and the software will automatically guide the positioning cursor to complete the positioning work

One click measurement

BINNA2; The front of the fixture platform is required with a one click measurement shortcut key, and the fixture locking sensing structure can automatically attach the current fixture locking status The software performs automatic measurement every time the fixture is locked

Automatic angle adjustment

BINNA2 & Nbsp; Implementation; Fully automatic adjustment of 0-12 ° ultra wide angle, with an adjustment accuracy of 0.003 °, allowing for; APC; More accurate angle measurement

Fully automatic focusing and calibration

BINNA2; Using the latest software and hardware platforms in dimensions; SANA2; On the basis of this, automatic focusing and automatic calibration functions have been added, making the entire measurement process more conventional; 100%; Automatically complete

Extremely fast detection speed

BINNA2; Excellent software and hardware design greatly improves the speed of testing, which can be applied in; 1.5s; Internal completion; The work includes end face analysis and surface morphology measurement, which can be done as soon as possible; 0.5s; Complete the testing of a single connector internally